Fire protection foam 90

Fire protection foam 90

FPFM-90-CBL-625ML

Individual price display after login

Exclusively for trade customers

Register now and access more than 2,000 products

Two-component fire protection foam with silicone base and outstanding fire protection properties

- Easy and quick sealing

- Especially well-suited for retrofitting

- Installation depth of just 15 cm

- No coating is required on cables under a diameter of 20 mm, cables larger than 20 mm should be coated with fire-retardant coating article No. 0893303006

- Fittings can be cut to any size

- 1 year shelf life even if used several times

Proof of Performance

- Wall and ceiling ducts fire-resistant Z-19.53-2358

- Wall and ceiling ducts fire-resistant R90 Z-19.53-2538

Notice

- Flammable pipes are to be processed with the Würth intumescent strip [68] according to approval Z-19.53-2538

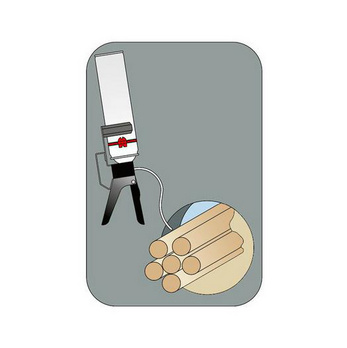

- Use suitable valve pliers

- Only for solid parts (with S 90 cable partitions). For pipe partitions, can also be used in light partition walls.

Clean opening

Clean opening

Affix ID plate

Affix ID plate

Introduce fire protection foam 90 (optionally, insert a shaped piece)

Introduce fire protection foam 90 (optionally, insert a shaped piece)

Smooth surface

Smooth surface

- Wall and ceiling ducts fire-resistant Z-19.53-2358

- Wall and ceiling ducts fire-resistant R90 Z-19.53-2538

Product information

Datasheets(X)

Application area

For installation in system [D1] with fire protection foam 90 [D1]

- For wall and ceiling ducts with a fire resistance class of "fire-resistant" in accordance with DIN 4102, part 9 for cables, cable bundles and cable support systems.

- For wall and ceiling ducts with a fire resistance rating of "fire-resistant" in accordance with DIN 4102, part 11 for flammable and non-flammable pipes.

- For walls and ceilings up to a maximum opening size of 500 cm2. The maximum height of 20 cm or maximum width of 50 cm may not be exceeded. For fire-resistant pipe ducts, an opening diameter of 25 cm must not be exceeded.

Instructions

- Always shake can well before use

- Fittings can be cut to any size

- If work is interrupted for longer than 5 minutes, replace the adapter

- Only for solid parts (with fire-resistant cable partitions)

When used with fire-resistant pipe partitions, can also be used in non-load bearing partitions

- Once the can is open, clean the valves with silicone remover art. no. 0893222600 and shake

Contents | 625 ml |

Container | Can |

Colour | Light grey (bright grey) |

Fire resistance rating | Fire resistant |

Yield (volume) approx. | 900 cm³ |

Min. ambient processing temperature | 0 °C |

Shelf life from production | 12 Month |

| Dimensions | ||

| Dimensions | fire-resistant Z-19.53-2358 | fire-resistant Z-19.53-2358 |

| Wall thickness | ≥ 100 mm | ≥ 100 mm |

| Ceiling thickness | ≥ 150 mm | ≥ 150 mm |

| Max. carcass opening | ≤ 500 cm2, however not higher than 20 cm or wider than 50 cm | ≤ 500 cm2, however not higher than 20 cm or wider than 50 cm, or dia. ≤ 25 cm |

| Installation depth | ≥ 150 mm | ≥ 150 mm |

| Installation of flammable pipes with Würth intumescent strips | |

| Pipe outside dia. | No. of windings |

| Dia. ≤ 32 mm | 1 layer |

| 32 mm ≤ dia. ≤ 75 mm | 3 layers |

| 75 mm ≤ dia. ≤ 110 mm | 4 layers |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!