Injectable mortar WIT-PE 510

Chemical injection mortar WIT-PE 510

ANC-MORT-(WIT-PE 510)-SBSCART-585ML

Art.-no. 5918615585

EAN 4062856827589

Register now and access more than 2,000 products

- Two-component resin mortar, pure epoxy, styrene-free

- Individual fixing point in cracked and uncracked concrete (M8 to M30)

Can be used with the following anchor rods: W-VI-A, W-VD-A, conventional threaded rods with inspection certificate 3.1 in accordance with EN 10204

- Post-installed rebar connection

The cartridge can continue to be used until the expiry date by replacing the mixing nozzle or resealing with the sealing cap

- Anchoring of threaded rods in natural stone (without approval/assessment)

- European Technical Assessment ETA-20/1038: Individual fixing point + cracked and uncracked concrete (W-VI-A anchor rod, W-VD-A anchor rod, commercial standard threaded rod with inspection certificate 3.1)

- European Technical Assessment ETA-20/1037: Post-installed rebar connection

This product is subject to the provisions of the Ordinance on the Prohibition of Chemicals (ChemVerbotsV). Detailed information on the hazards arising from this product, the precautionary steps to be taken during proper use, adequately dealing with spillages or other exposure and ensuring correct disposal can be found in the material safety data sheet.

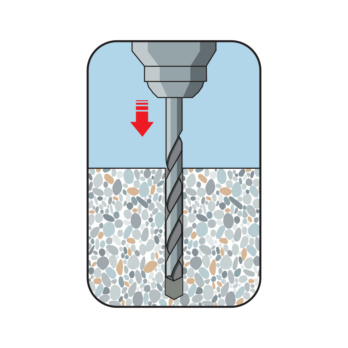

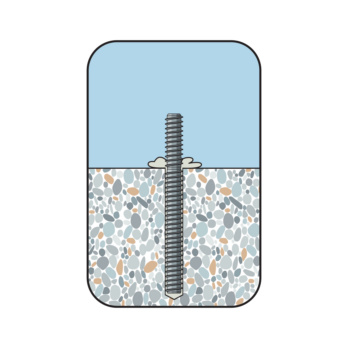

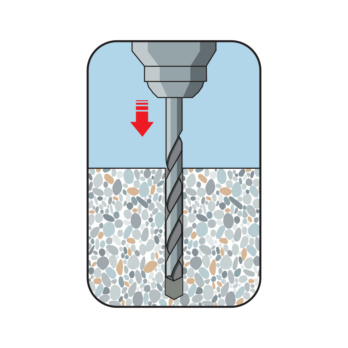

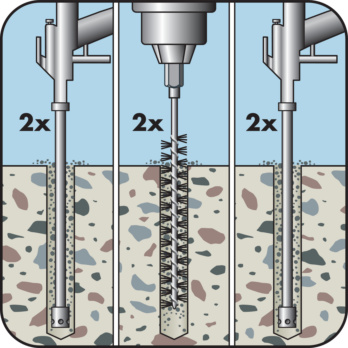

Drill the hole

Make the drill hole using Würth hollow drill bit, there is no need for hole cleaning

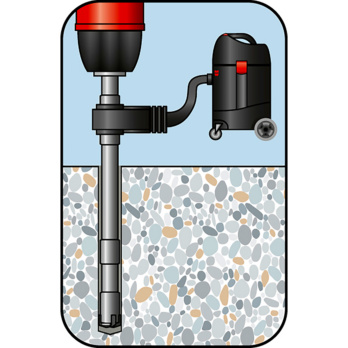

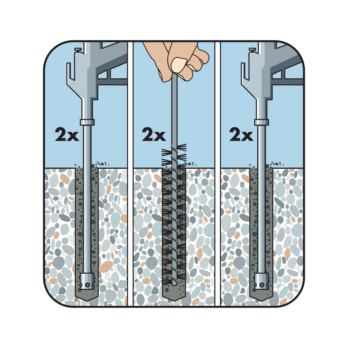

Clean the drill hole:

Blow out 2x with oil-free compressed air (min. 6 bar)/brush out 2x/blow out 2x with oil-free compressed air (min. 6 bar)

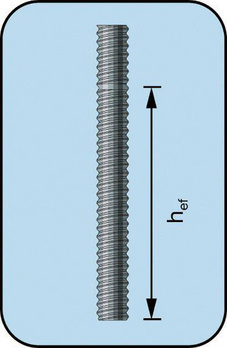

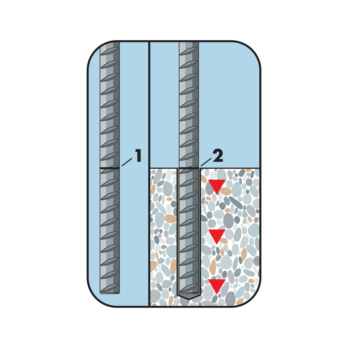

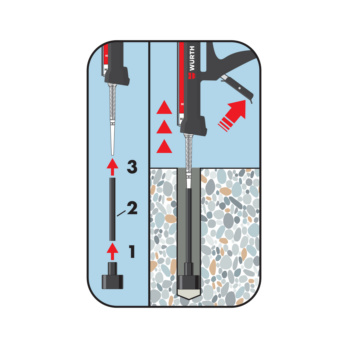

Cut anchor rod to length and mark the desired insertion depths

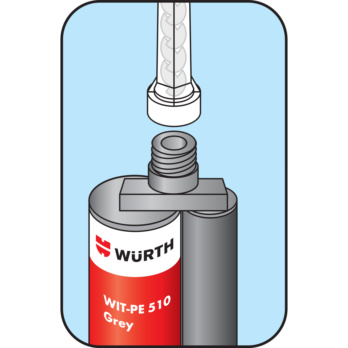

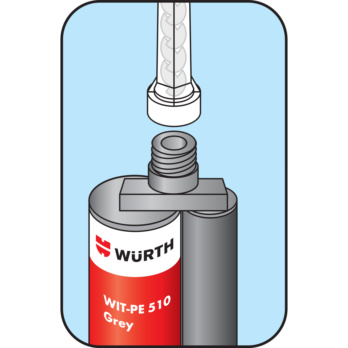

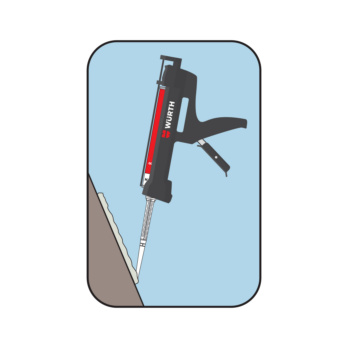

Screwing the mixer onto the cartridge

Discard the first section of mortar (until the mortar is uniformly coloured - approx. 10 cm)

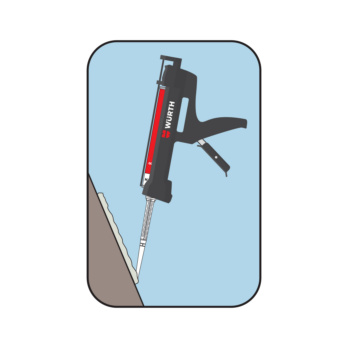

Fill injection mortar starting from base of drill hole

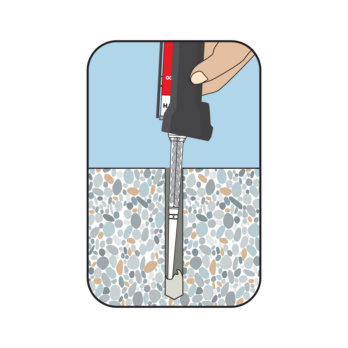

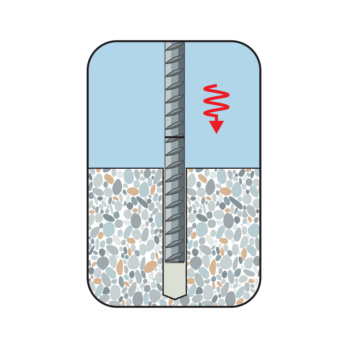

Press in anchor rod up to drill hole base while turning slightly

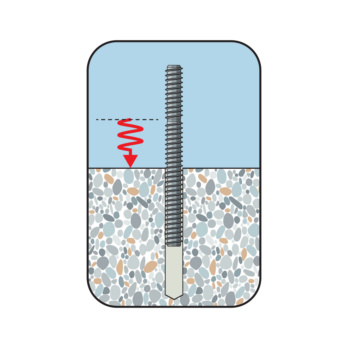

Visual check of mortar volume, embedment depth mark

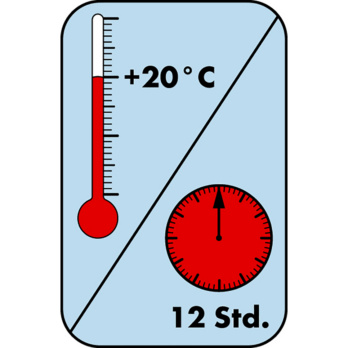

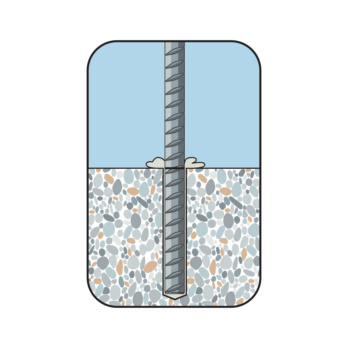

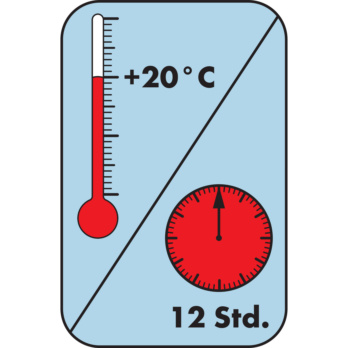

Load can be applied to the reinforcement bar after observing the curing time

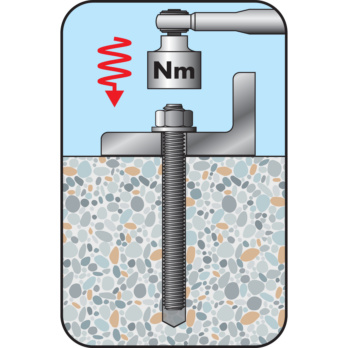

Install component, apply installation torque

Drill the hole

Drill the hole using a Würth dust extraction drill bit. The drill hole does not require cleaning

Clean the drill hole:

Blow out 2x with oil-free compressed air (min. 6 bar)/

brush out 2x/

blow out 2x with oil-free compressed air (min. 6 bar)

Place the embedment depth mark on the rod and check the drilling hole depth

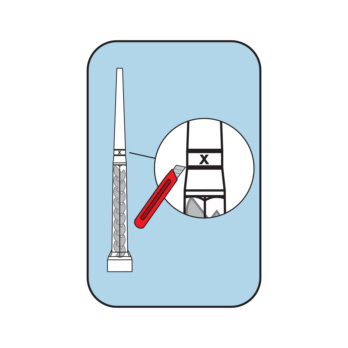

Use WIT-VL 16 Cut off mixer at position "X"

Screwing the mixer onto the cartridge

Discard the first section of mortar (until the mortar is uniformly coloured - approx. 10 cm)

Mount injection equipment, fill injection mortar from bottom of drill hole

Insert the reinforcement bar until it reaches the mark, turning slightly

Visual check of the mortar volume, observe maximum processing time

Load can be applied to the reinforcement bar after observing the curing time

- European Technical Assessment ETA-20/1038: Individual fixing point + cracked and uncracked concrete (W-VI-A anchor rod, W-VD-A anchor rod, commercial standard threaded rod with inspection certificate 3.1)

- European Technical Assessment ETA-20/1037: Post-installed rebar connection

This product is subject to the provisions of the Ordinance on the Prohibition of Chemicals (ChemVerbotsV). Detailed information on the hazards arising from this product, the precautionary steps to be taken during proper use, adequately dealing with spillages or other exposure and ensuring correct disposal can be found in the material safety data sheet.

Datasheets(X)

- Suitable for attaching metal structures, metal profiles, wooden structures, brackets, pipes, cable conduits, etc.

- Suitable for structural expansions, ceiling and wall outlets, expansion of load-bearing structures, reinforcement of load-bearing structures, attachment of balconies and canopies, sealing of temporary openings and "forgotten" reinforcing bars

Container | Cartridge |

Contents | 585 ml |

Suitable application gun | HandyMax 585 ml, Application gun MULTI, Pneumatic application gun 585ml, Battery-powered application gun 585ml |

Min./max. processing temperature /conditions | 5 to 40 °C / temperature in the anchorage ground during processing and hardening |

Min./max. ambient temperature / Conditions | -40 to 70 °C / after completely curing process |

Temperature resistance, long-term temperatures max. | 43 °C |

Temperature resistance, short-term temperatures max. | 70 °C |

Shelf life from production/conditions | 24 Month / cool and dry storage area, 5°C to 25°C |

Approval | ETA-20/1037, ETA-20/1038 |

Chemical basis | Pure-Epoxy, styrene free |

Colour | Grey |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!