Painter's acrylic

Painter´s acrylic

ACRYSEAL-FLEX-PAINTER-WHITE-310ML

Register now and access more than 2,000 products

Excellent adhesion for commercially available paints and plasters and can be both painted and plastered over

Due to the wide variety of paint and lacquer formulas available, we recommend that you always carry out preliminary testing in order to rule out any interactions. Caution: Sealant joints that have been fully painted over tend to crack when movement occurs in the joint, as the applied paint is generally less elastic than the sealant.

- Highly elastic

- Broad adhesive range on a variety of standard construction surfaces

- Building material class B2 in accordance with DIN 4102

- Silicone-free

- Resistant to ageing, weathering and UV

- Odourless

Our products featuring the EMICODE label are low-emission/low in harmful substances. The EMICODE classification system awards labels to construction products that comply with the very stringent health and environmental requirements of recognised institutes.

- Not suitable for use in building construction joints in accordance with DIN 18540

- Due to the wide variety of paint and glazing formulations, preliminary testing is required in order to rule out any interactions

- Take care with sealant joints that have been fully painted over. These tend to develop cracks when movement occurs in the joint, as the applied paint is generally less elastic than the sealant and then causes cracks to form in the paint

- The setting speed is dependent on the application temperature, the weather and the substrate moisture. The setting speed is significantly delayed in cold, damp weather

- Discolouration may occur in wood containing tannic acid

- For vertical joints, please observe the run-off behaviour of the sealant

- May cause corrosion on metals such as steel, copper and zinc plated surfaces

- Standing water should be prevented in the acrylic joint as this can lead to erosion

- Acrylic is very unstable in terms of water absorption and release. Since the diffusion behaviour also changes as a result of the differences in water adsorption in the material, neither the water vapour diffusion resistance (μ) nor the diffusion-equivalent air layer thickness (SD) can be measured on this material in accordance with DIN EN 12572. The value of 5,000 is the average value obtained through testing.

- Not to be used in conjunction with pre-compressed sealing tapes

- Not suitable for bonding or filling cavities

- Due to the wide variety of paint and glazing formulations available, always carry out your own tests on the area first, especially on alkyd resin paints and powder-coated aluminium

- Sufficient ventilation should be ensured during the curing phase

- A higher coating thickness extends the curing time

- The joint dimensions must be observed, wide joints in particular should be pre-filled with PE backer rod

Tested in accordance with EN 15651 Part 1

- Fire behaviour: Class E

- Stability under load: ≤ 3 mm

- Volume loss: ≤ 25 %

- Tensile behaviour after immersion in water (at 23°C), ductile: ≥ 100 %

- Durability: Passed

EMICODE EC1plus: Very low emissions: The EMICODE classification system distinguishes the environmental and health compatibility of construction products. The lowest-emission products bear the EC1plus mark.

The usage instructions are recommendations based on the tests we have conducted and our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee consistent quality of our products. We reserve the right to make technical changes and further develop products.

Datasheets(X)

- For sealing indoor and outdoor expansion joints

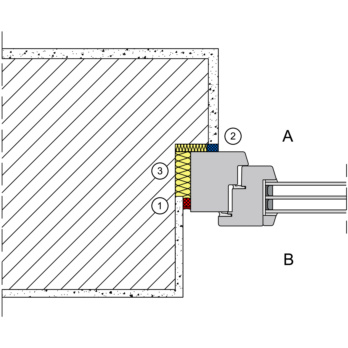

- For window sealing in the system with Window and façade-tight. The painter's acrylic is used for indoor sealing and the window and façade sealant for the outdoor sealing.

- Adhesion surfaces must be clean, dry and firm

- A primer, e.g. with Silicone primer, improves the adhesion for absorbent or porous surfaces

- Please observe the "General Notes on Application for Sealants" overview sheet. For more information, please refer to the technical data sheet.

| |

Container | Cartridge |

Contents | 310 ml |

Fungicidal properties | No |

Colour | White |

Chemical basis | Acrylic resin dispersion |

Density | 1.57 g/cm³ |

Continuous motion absorption | 20.0 % |

Smell/fragrance | Characteristic |

Full curing speed | 1 mm/d |

Fully hardening/curing conditions | 23°C and 50% relative humidity |

Min. skin-formation time | 10 min |

Min. breaking elongation | 250 % |

Breaking elongation conditions | for 2-mm film |

Conditions for skin-formation time | at 23°C and 50% relative humidity |

Shore A hardness | 10 |

Min./max. temperature resistance | -20 to 80 °C |

Min./max. processing temperature | 5 to 40 °C |

Recoatable/Can be painted over | Yes |

Water-vapour diffusion resistance factor value µ | 24000 |

Surface pre-treatment required | On absorbent or porous surfaces |

Mixing ratio | Mixing ratio of painters acrylic to water = 1:5 to 1:10 |

Ultraviolet resistance | Yes |

Coating compatibility | Yes |

Shelf life from production | 24 Month |

Conditions to maintain shelf life from production | at 5°C to 25°C |

Sustainability | Pollutants / Emissions |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!